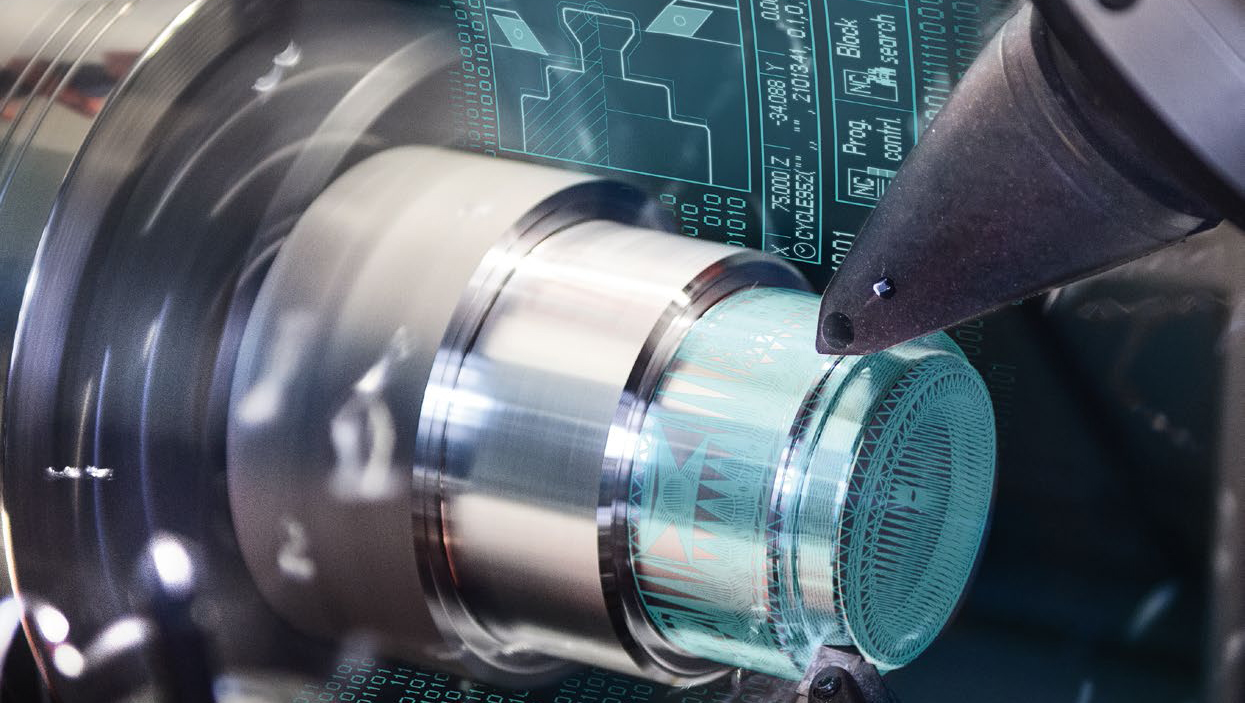

CNC machining is among the fastest manufacturing strategies available today. It creates required parts with the help of programmed software much more efficiently than any manual manufacturing ever could.

There are several types of CNC machines available today, such as CNC milling machines, CNC turning machines, and EDM machines. Shops like LOCUS Precision are offering all sorts of CNC machining services to anyone who needs them.

It is incredibly important to go for the right manufacturing techniques while doing any project. Some people may still like and prefer manual machining, but nothing is better than CNC machining.

The Advantages of CNC Machining

CNC machining comes with boundless advantages, some of which are discussed below:

- Versatility and Consistency

CNC machines come with incredible precision and versatility. That’s why almost all industries today are using CNC machining to produce precision parts and components. The more precise parts are, the more valuable they become. CNC machining offers.

- Precision fabrication of parts

- Profitable production

- Efficiency

- Consistent cuts

CNC machining enables us to produce custom metals. When it comes to the large-scale cutting of material, especially metal, CNC machining is the best method.

- Reliability and Efficiency

Since CNC machines are computerized and automated, they are incredibly accurate. There are very few chances of errors while using a CNC machine, as opposed to manual machines. That’s why they are more reliable, fast, and efficient.

- Less Labor and Low Maintenance

CNC machines are automated, which is why they don’t require large-scale human labor. Just a few engineers can run many CNC machines and produce parts on a large scale. But, the engineers have to be very skilled at executing production tasks.

CNC machines also need low maintenance and care. Even though you can run CNC machines all day long, they will still not need a lot of care, as opposed to manual machines.

- Design Uniformity and Safety

CNC machines are popular for precisely replicating and repeatedly making the same parts. Since the dimensions and programming don’t change, the components that are made remain uniform in all ways.

So, even though they increase the profit, they don’t require more effort, which is why they are the best. Operators are usually not near CNC machines. So, if anything bad happens, they will be safe. Therefore, CNC machines are also safer than manual machines.

Conclusion

CNC machining is the best method for all sorts of manufacturing and large-scale productions. It is more efficient, reliable, precise, accurate, safe, and inexpensive compared to manual machining. CNC machines require less maintenance and have more demand in industries.